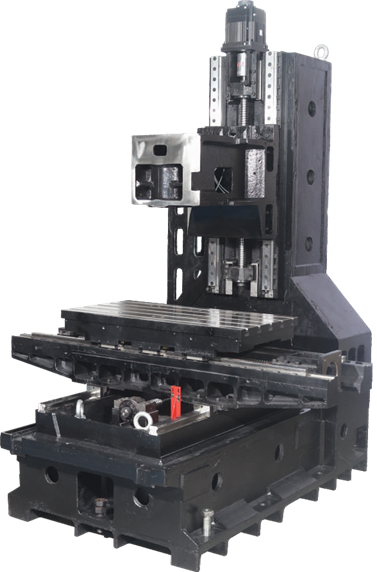

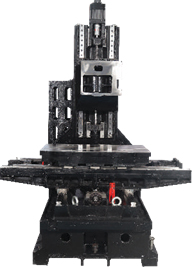

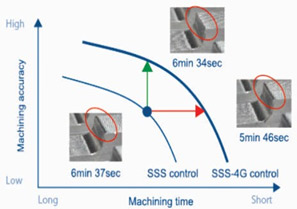

The ARJUN Plus V series is integrated with brand new exterior designs, demonstrating highest stability along with great configuration. This series offers high performance, high precision and high speed at an economical price.

36/36/24 m/min

2.5 Sec.

24 Tools

On Sudden Power failure and Emergency stop

For easy chip flow

with wider span guide ways

High precision LM Guides

For high Precision Surfacing

| Specification | ARJUN Plus V 850 |

| Axis Travel | |

| X-Travel | 850mm |

| Y-Travel | 500mm |

| Z-Travel | 550mm |

| Spindle Nose to Table Surface | 150 – 700mm |

| Work Table | |

| Table Surface Dimension (X, Y) | 1000 x 500mm |

| T-Slot Dimension/ No./ Pitch | 18mmx5x100mm |

| Table Height | 900mm |

| Maximum Table Weight | 800 kg |

| Spindle | |

| Spindle Motor Power (Cont./30 min) | 7.5/11 Kw |

| Spindle Motor Coupling | Belt Driven |

| Spindle Speed | 8,000 rpm, 10,000/12,000 rpm |

| Tool Type | BT #40, 5-bearing spindle – 2-Front, 3-Rear |

| Spindle Bearing - Inner Diameter | 70mm |

| Spindle Material / Hardness | Shaft SAE 8620 / HRC 58-60 |

| Spindle Runout | 0.002mm At Bore Taper ,On 300mm Mandrel – 0.010mm |

| Retention System / Holding Capacity | 850 ± 100 KgF |

| Axis Feeds | |

| Rapid Traverse – X/Y/Z | 36/36/24 m / minute |

| Rated Cutting Feedrate – X/Y/Z | 10/10/10 m/min. |

| Mechanical Way System – X/Y/Z | 35/45/45mm width |

| Axis Drive Motor Power – X, Y/Z | 3/3/3 Kw |

| Axis Thrust Force – X, Y/Z | 22.5/22.5/22.5 Nm |

| Ballscrews – X, Y, Z | 40mm Ballscrews, 12mm Pitch |

| Positioning Accuracy – X/Y/Z | 0.010mm |

| Positioning Repeatability – X/Y/Z | 0.006mm |

| Least Input Command Increment | 0.001mm |

| Tool Changer | |

| Tool Capacity | 24-Tools, Arm Turret (Option) |

| Tool Shank | BT#40,BBT 40 (Option) |

| Tool Change Time | 2.5-sec. tool-to-tool, |

| Maximum Tool Diameter / with adjacent tool |

75mm with no adjacent tool/ 150mm w/o Adj. Tool |

| Maximum Tool Length / Weight | 250mm / 8 kg |

| Tool Selection / Tool Access | Random access Bi-directional shortest path |

| Specifications | |

| Air Service Requirements | 6 Kg/cm2 |

| Connected Load | 22 Kva |

| Coolant Tank Capacity | 350 liters |

| Coolant Pump - LPM /Pressure | 200 LPM , 2 Bar |

| Floor space requirements (L x W x H) | 2250x2750x2900 mm |

| Machine Weight | 5600 kg |

| Warranty | 1 year warranty for Machine Tool 2 year warranty for Controller |